|

|

Post by nosedamage on Nov 2, 2007 8:16:12 GMT 1

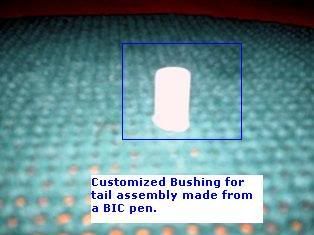

Here is a little field repair tip that I figured out, sorry if this is duplicated, I did not see it in a search of the thread: If the rudder and elevator assembly and your fuse becomes hollowed out from a crash simply use a BIC pen body to create a solid shaft for the tail assembly to slide into. I cut approx 1/4 inch sections of the pen and slid it onto the rudder assembly screw shafts and then placed a little AC on it and push it in the elevator and fuse holes. Tighten the screws and viola no more movement with the Rudder and elevator assembly. I tried it with no AC and it works just as well. I see some benefits to using this as a solution to the rigid screw shaft possibly hollowing out the holes of the elevator and fuse. Does anyone have any reasons why this may not be a good idea? Sorry for the crappy pics( camera does not like white gloss)     TIA Nosedamage |

|

|

|

Post by mrmugen on Nov 2, 2007 17:09:36 GMT 1

Great idea! I have two sloppy tails on planes that will see this mod. Thanks for your input!

|

|

hack73

Squadron leader

Posts: 154

|

Post by hack73 on Nov 12, 2007 19:34:11 GMT 1

Nosedamage,

Did your mod this weekend and it works beautifully! Tail end is solid, no movement.

|

|

|

|

Post by mararra on Nov 13, 2007 2:32:02 GMT 1

Very good idea, there Nose, you must be a born engineer. Only thing I could come up with is thin double stick foam tape between the plastic elev/rud fitting and the top of th fuse. Works good so far. it eliminates sheer forces from enlarging the dowel holes in the fuse. ;  |

|

|

|

Post by nosedamage on Nov 15, 2007 9:16:25 GMT 1

Sweet! I am glad to contribute to this community that I learned so much from! So far I have taken the tail off twice at the plastic molding and this mod has held true.

Did you cover the entire shaft or just enough to penitrate the dowel holes? Since I am Cubless at the moment I am thinking when my new one comes in I am going to cover the entire shaft.

|

|

hack73

Squadron leader

Posts: 154

|

Post by hack73 on Nov 15, 2007 18:35:06 GMT 1

I had cut mine to fit just the thickest part of the shaft. It stops a hair before it starts getting smaller.

|

|

|

|

Post by mararra on Nov 16, 2007 1:53:25 GMT 1

I used the double sticky tape to ahere the plastic rudder/elevator fitting to the surface of the fuse. Didn't think about shimming the hole where the post goes thru. But, you can be sure I'll use your mod when I rebuild.

|

|

cloud9

Flying officer

Posts: 12

|

Post by cloud9 on Nov 17, 2007 3:13:35 GMT 1

Another thing to do is put a ring of epoxy around the holes in the stabilizer before assembling the plane. This has kept my stab tight. But it won't deal with looseness in the fuse, as the above idea does.

Jim

|

|