Post by duck9191 on Aug 16, 2007 4:16:43 GMT 1

after breaking off my negative wire off my dean connector on my receiver i decided i needed longer leads.

what you will need: soldering iron, wet sponge, solder, wire cut to desired length, wire cutters.

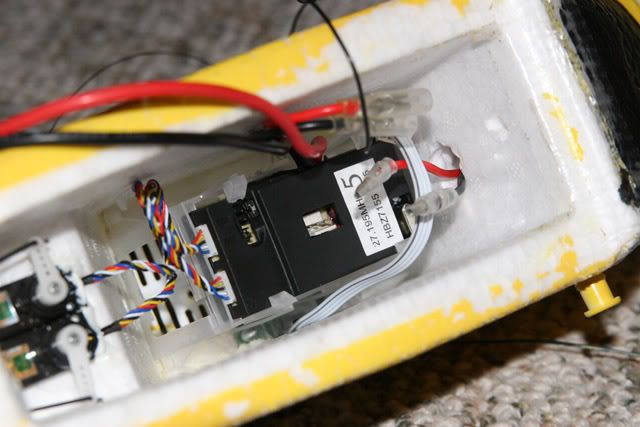

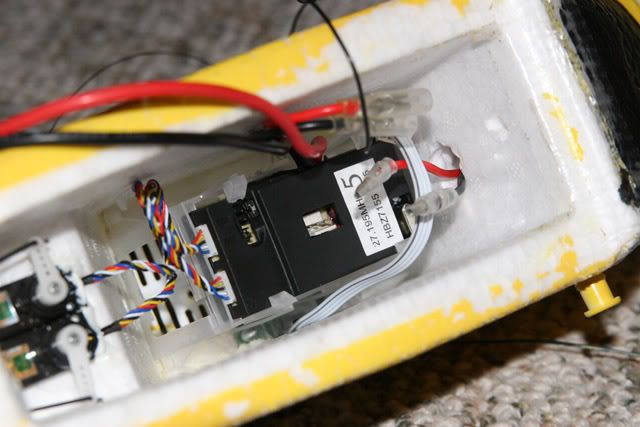

1. remove the receiver. make sure everything is disconnected before you rip it out.

2. remove the case from the pcb, do this by clipping the tab on the side of the box.

3. find the wires one the back of the pcb, they are right next to the motor wires, don't get them mixed up, that wouldn't be good. now after your sure you have the wires that the red arrows in the pic are pointing to take your soldering iron and melt the solder and pull out the wire. be careful not to over heat anything, or melt something that you don't want to or desolder anything else. do the same to the other wire.

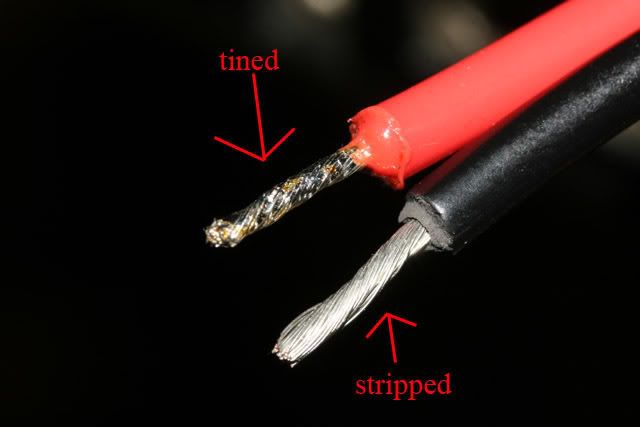

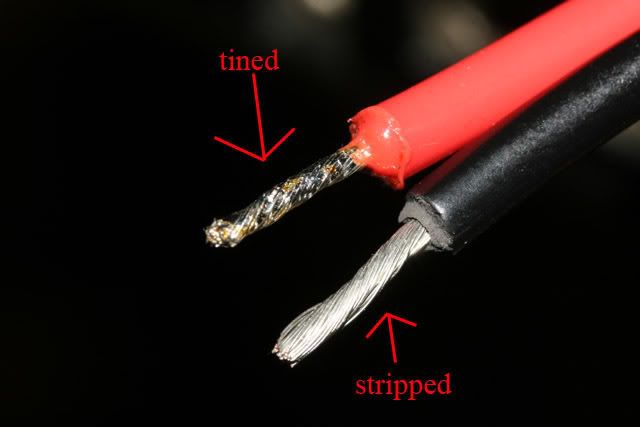

4. now on to the new wire. now would be a good time to swap over your connectors, hopefully you will take advantage of the situation and switch to dean and save your self some head aches later. if you do switch over to deans make sure you tin both the wire and the connector, and be sure to let the solder joint cool before handling. if you are going to stick with the mini tymia that comes with the cub you could either solder the new and old wires together or you could try to re-crimp the pins on the new wire, but i wouldn't try that. make sure you put heat shrink tube on the wire, forgetting it and getting soldered is not fun, believe me lol.

5. strip and lightly tin the other ends of the wire for the receiver. the holes in the pcb for the wires are small, so 18ga wire or maybe 16 if you enlarge the holes slightly are about the biggest that will fit. make sure you ends are straight and smooth.

6. this may require two people, or a hobby vise. secure the pcb and line up the wire and the hole in the pcb, now heat the solder on the back of the pcb until the wire pushes through the hole. hold the iron there for a few seconds until the solder on the wire is melted. carefully remove the iron and use the sponge to cool the board. do the same to the other wire. now the hard part is done yay.

7. the receiver box may need to be modded to fit the wires depending on what size you went with. i used the wire cutters and nipped out a little bit nothing to hard.

8. now reassemble everything. now is a good time to check out the battery box and servo to make sure they are still in place and arnt going anywhere. also make sure you servos are connected correctly, getting in the air and finding out then is not good.

9. now either grab a beer and enjoy your handy work, or go out in fly and enjoy your battery having a longer leash.

as a final though, remember that the longer the wire, th higher the resistance which will cause the wire to become warm, or hot if to long and can diminish performance of the battery and plane.the only way to combat this is heavier gage wire, but i don't think anything larger then 18ga will fit with out modifying the hole in the pcb. my wires are probably about the longest you would want to go, they don't get warm and the motor seems to have the same amount of power, but when i swap to a brushless setup i might need to shorten them.

what you will need: soldering iron, wet sponge, solder, wire cut to desired length, wire cutters.

1. remove the receiver. make sure everything is disconnected before you rip it out.

2. remove the case from the pcb, do this by clipping the tab on the side of the box.

3. find the wires one the back of the pcb, they are right next to the motor wires, don't get them mixed up, that wouldn't be good. now after your sure you have the wires that the red arrows in the pic are pointing to take your soldering iron and melt the solder and pull out the wire. be careful not to over heat anything, or melt something that you don't want to or desolder anything else. do the same to the other wire.

4. now on to the new wire. now would be a good time to swap over your connectors, hopefully you will take advantage of the situation and switch to dean and save your self some head aches later. if you do switch over to deans make sure you tin both the wire and the connector, and be sure to let the solder joint cool before handling. if you are going to stick with the mini tymia that comes with the cub you could either solder the new and old wires together or you could try to re-crimp the pins on the new wire, but i wouldn't try that. make sure you put heat shrink tube on the wire, forgetting it and getting soldered is not fun, believe me lol.

5. strip and lightly tin the other ends of the wire for the receiver. the holes in the pcb for the wires are small, so 18ga wire or maybe 16 if you enlarge the holes slightly are about the biggest that will fit. make sure you ends are straight and smooth.

6. this may require two people, or a hobby vise. secure the pcb and line up the wire and the hole in the pcb, now heat the solder on the back of the pcb until the wire pushes through the hole. hold the iron there for a few seconds until the solder on the wire is melted. carefully remove the iron and use the sponge to cool the board. do the same to the other wire. now the hard part is done yay.

7. the receiver box may need to be modded to fit the wires depending on what size you went with. i used the wire cutters and nipped out a little bit nothing to hard.

8. now reassemble everything. now is a good time to check out the battery box and servo to make sure they are still in place and arnt going anywhere. also make sure you servos are connected correctly, getting in the air and finding out then is not good.

9. now either grab a beer and enjoy your handy work, or go out in fly and enjoy your battery having a longer leash.

as a final though, remember that the longer the wire, th higher the resistance which will cause the wire to become warm, or hot if to long and can diminish performance of the battery and plane.the only way to combat this is heavier gage wire, but i don't think anything larger then 18ga will fit with out modifying the hole in the pcb. my wires are probably about the longest you would want to go, they don't get warm and the motor seems to have the same amount of power, but when i swap to a brushless setup i might need to shorten them.