Post by flydiver on Aug 15, 2008 15:55:36 GMT 1

Just discovered my 2nd problem with cracked solder joints on the ESC/RX box. This is evidenced by one servo (generally) that exhibits strange behavior. It may seem to be OK on bench testing but on flight that channel makes the plane fly erratically. A new flier will swear they are a victim of 27mHZ glitching and immediately go out an buy a Spectrum something-or-another. It's OK-it's a good excuse-you'll need it in the future anyway since 27mHz is a dead end. ;D

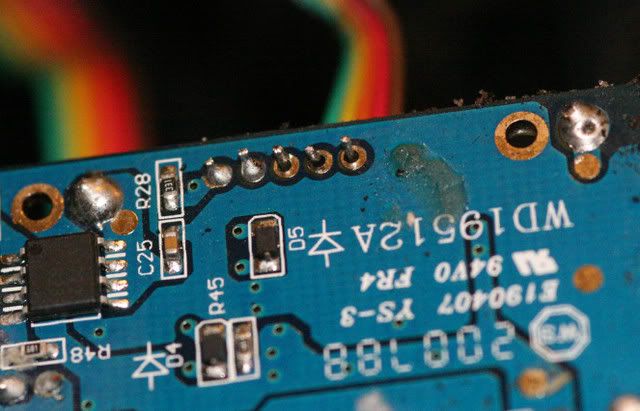

The solder joint where the servo socket connects to the PCB board cracks (back underside). Those little buggers fit in there really tight (thanks PZ) and it only takes a few removal cycles to flex and crack the joint.

The 'resting' joint (unstressed bench test) may work fine but under flying stress and vibration the joint opens and closes and that servo goes nuts. Elevator is particularity bad, so that's the one that seems to go.

You can see the crack under STRONG magnification or reproduce it by wiggling the base of the wire while it's powered. A good joint won't do anything when you move the wire base-a bad one makes the servo jump all over. If the servo jumps around that's likely the problem.

Don't confuse this with a bad/worn POT on a servo or servo binding. A worn POT will jitter a little but not react to moving the wire. A servo that is binding will settle right down if you remove the control link and won't move either if you jiggle the wire.

A bad joint makes erratic large jumps and quits when you stop messing with the wire or giving control inputs.

Replace the ESC/RX or re-solder. I've re-soldered both now with a VERY fine tipped iron and strong magnification. Just baaarrrreeellly touch it to re-melt the solder with an extremely small blob of new solder to add. If you solder adjacent poles together I think you probably blew it. Same if you slop the solder on.

Once confirmed as fixed again epoxy the hell out of the solder joint and servo socket. DON'T get epoxy in the opening or you've ruined all your work.

fly

The solder joint where the servo socket connects to the PCB board cracks (back underside). Those little buggers fit in there really tight (thanks PZ) and it only takes a few removal cycles to flex and crack the joint.

The 'resting' joint (unstressed bench test) may work fine but under flying stress and vibration the joint opens and closes and that servo goes nuts. Elevator is particularity bad, so that's the one that seems to go.

You can see the crack under STRONG magnification or reproduce it by wiggling the base of the wire while it's powered. A good joint won't do anything when you move the wire base-a bad one makes the servo jump all over. If the servo jumps around that's likely the problem.

Don't confuse this with a bad/worn POT on a servo or servo binding. A worn POT will jitter a little but not react to moving the wire. A servo that is binding will settle right down if you remove the control link and won't move either if you jiggle the wire.

A bad joint makes erratic large jumps and quits when you stop messing with the wire or giving control inputs.

Replace the ESC/RX or re-solder. I've re-soldered both now with a VERY fine tipped iron and strong magnification. Just baaarrrreeellly touch it to re-melt the solder with an extremely small blob of new solder to add. If you solder adjacent poles together I think you probably blew it. Same if you slop the solder on.

Once confirmed as fixed again epoxy the hell out of the solder joint and servo socket. DON'T get epoxy in the opening or you've ruined all your work.

fly