Post by flydiver on Jul 19, 2008 5:20:45 GMT 1

Late follow-up on the 3mm carbon rod wing reinforcement.

It's been over a year of flying. The Cub was passed on to a friend learning to fly. He has limited talent and lives in a kind of windy area. He has completely destroyed an Easy Star (formidable task), can't fly a Slow Stick to save his life (he thinks it's jinxed, flies fine for me), and has really liked and beat the stuffing out of the Cub.

In addition to the wing reinforcement the tail had been broken off and similarly reinforced with 2 strips of 3mm carbon on each side.

He as managed to rip out the battery box, break the tail feathers several times (but not break the tail off), destroy 2 motors and a couple of gearboxes, and the wing saddle (also reinforced) has still been all beat up. He tore the reinforcement out.

He finally cracked the wing. It did not break. Significant crack right where the carbon is glued into the brass rod. In checking the break area I noticed flex in the same spot on the other joint.

Crack was injected with Sumo glue and taped up to cure.

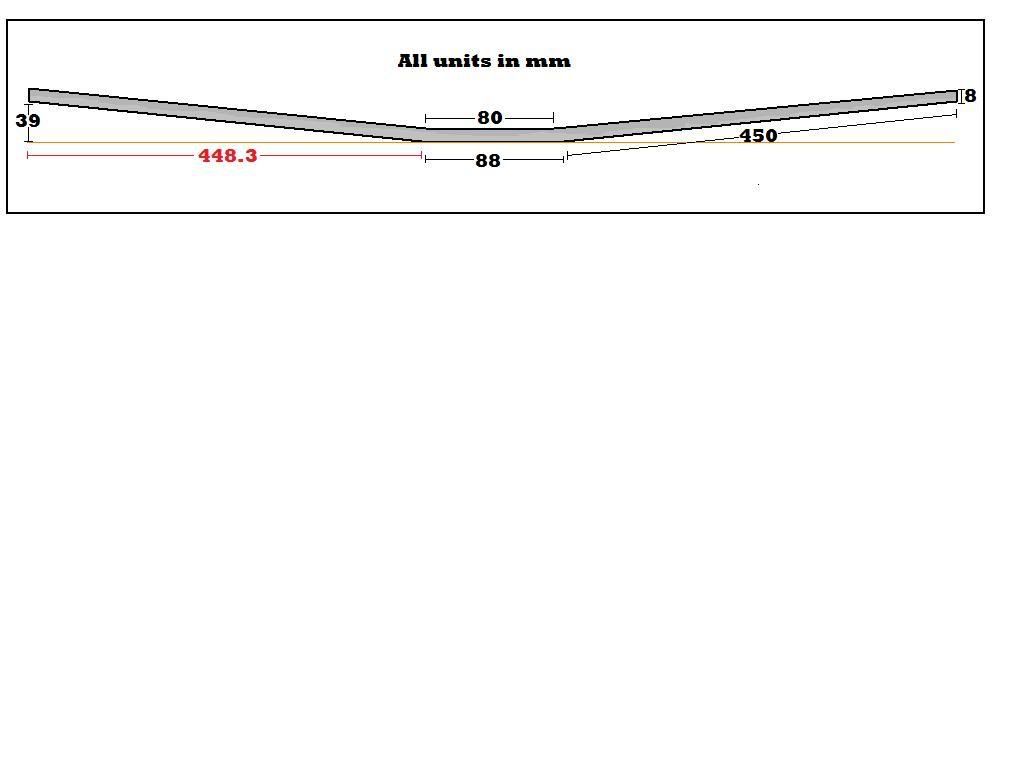

Once set I cut a foot long slit about 6 mm deep about an inch from the carbon rod. It started about 1" inside the angle where the flat area for the wing mount is. I then epoxied in a 0.5 x 5mm carbon flat [http://www.bphobbies.com/view.asp?id=V628175&pid=A3628036] into the slit. This can insert completely into the wing and is almost invisible. The carbon flat bends easily on the flat side but is EXTREMELY rigid trying to bend edge wise in this use.

I think if I was going to do a new wing reinforcement I would use this carbon flat technique for the whole wing rather than the rod. Rod is strong but flexes which led to the failure at the brass joint. Now, it has taken some serious abuse to get to that point though. You would need 3 pieces- one for each wing half and a short one to bridge the saddle area.

It's a pretty easy mod. A straight edge, exacto knife, some epoxy, and the carbon.

For the broken tail I did a similar thing to the original wing fix just using bamboo skewers like the wing rod. Burned a groove with a fine soldering tip and epoxied bamboo in place. Covered with red tape. Tough tail feathers now. Faster than a 2 hour trip to the LHS for new feathers.

fly

It's been over a year of flying. The Cub was passed on to a friend learning to fly. He has limited talent and lives in a kind of windy area. He has completely destroyed an Easy Star (formidable task), can't fly a Slow Stick to save his life (he thinks it's jinxed, flies fine for me), and has really liked and beat the stuffing out of the Cub.

In addition to the wing reinforcement the tail had been broken off and similarly reinforced with 2 strips of 3mm carbon on each side.

He as managed to rip out the battery box, break the tail feathers several times (but not break the tail off), destroy 2 motors and a couple of gearboxes, and the wing saddle (also reinforced) has still been all beat up. He tore the reinforcement out.

He finally cracked the wing. It did not break. Significant crack right where the carbon is glued into the brass rod. In checking the break area I noticed flex in the same spot on the other joint.

Crack was injected with Sumo glue and taped up to cure.

Once set I cut a foot long slit about 6 mm deep about an inch from the carbon rod. It started about 1" inside the angle where the flat area for the wing mount is. I then epoxied in a 0.5 x 5mm carbon flat [http://www.bphobbies.com/view.asp?id=V628175&pid=A3628036] into the slit. This can insert completely into the wing and is almost invisible. The carbon flat bends easily on the flat side but is EXTREMELY rigid trying to bend edge wise in this use.

I think if I was going to do a new wing reinforcement I would use this carbon flat technique for the whole wing rather than the rod. Rod is strong but flexes which led to the failure at the brass joint. Now, it has taken some serious abuse to get to that point though. You would need 3 pieces- one for each wing half and a short one to bridge the saddle area.

It's a pretty easy mod. A straight edge, exacto knife, some epoxy, and the carbon.

For the broken tail I did a similar thing to the original wing fix just using bamboo skewers like the wing rod. Burned a groove with a fine soldering tip and epoxied bamboo in place. Covered with red tape. Tough tail feathers now. Faster than a 2 hour trip to the LHS for new feathers.

fly